Facilities

Turbine

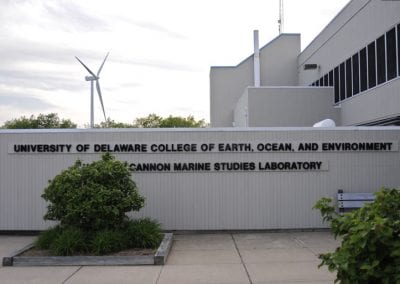

The University of Delaware’s 2 megawatt Gamesa G90 turbine, in Lewes, Delaware, offers opportunities for UD faculty and professionals, as well as Gamesa engineers, to conduct research on a modern, commercial wind turbine. UD and Gamesa have jointly trained both maintenance staff and selected researchers to safely access the turbine to take measurements and install instrumentation. Proposals are vetted by a joint UD-Gamesa R&D committee that considers safety, minimal disruptions to operations, and scientific or engineering value of the proposed research.

As of spring 2012, ongoing projects include studies of corrosion from salt spray, wind force against the drive train, tower vibration, net costs and benefits of wind power, new gearbox monitoring for detection of precursors of faults, and bird and bat impacts. The turbine is located at UD’s Hugh R. Sharp Campus in Lewes and provides sufficient electricity to power the entire campus (two lab and office buildings, a conference center, and harbor for two ships), with extra going to the local grid. A joint venture created and owns the turbine, First State Marine Wind, a partnership between UD-owned Blue Hen Wind and Gamesa USA; funding was provided by the University of Delaware, Gamesa USA, and the US Department of Energy.

To see a video of the turbine being built and monitor real-time operations and power output, visit www.ceoe.udel.edu/LewesTurbine.

Wind profiler

Thanks to a collaboration between the University of Delaware, the Delaware Department of Natural Resources and Environmental Control, the Delaware Environmental Observing System, and First State Marine Wind, a 915-MHz wind profiler was placed in Cape Henlopen State Park, Lewes, DE, about half a kilometer from the Atlantic coast.

For details about the profiler click this link. It has been operational for since late 2013 and recently it has been feeding into the NOAA profiler website. To use the website, under Site Name choose: Lewes, DE (LWSDE), then you can click on: Get Plot to see the latest graph. We hope that you will find it useful for topics such as model verification and initialization, characterization of the vertical structure of the marine environment, and wind power research along the US East Coast.

Lab equipment

A better understanding of gearbox wear, and of bearing and gear failures, would be valuable to the design and operation of wind turbines, potentially reducing mechanical failures and improving predictability of future failures. In order to subject bearings to controlled conditions and test for effect on surfaces, a new instrument is under development.

For the wind turbine application, we have determined that the following are important: 1) control over temperature, lubrication contaminants, roughness, and slip ratio; 2) continuous access for surface characterization during testing. A thrust bearing arrangement (as to a radial bearing) offers these important degrees of freedom. We will have full control of the testing conditions while retaining continuous access to the contacting surfaces for characterization. The slip ratio can be controlled using rollers and annuli of varying thickness.

This instrument is part of the UD Tribology Lab, Principal Investigator is Prof. David Burris.